Incubator Group

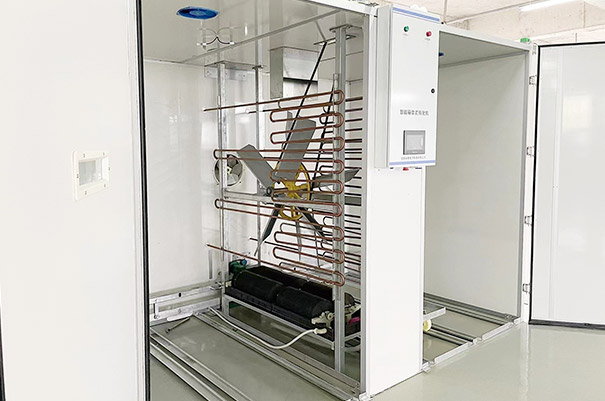

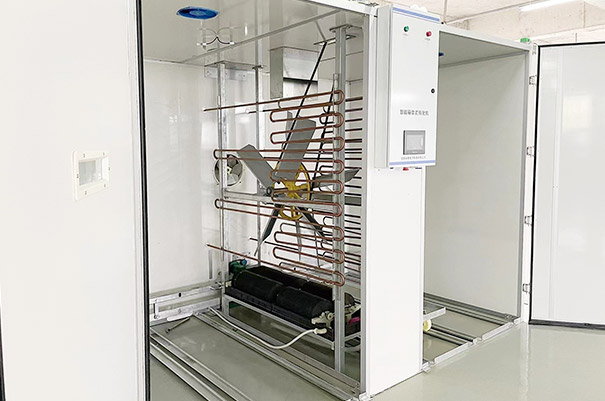

OUKE incubator can not only automatically turn eggs, automatically adjust temperature and humidity, etc., but also monitor various indicators during the incubation process in real time through an intelligent monitoring system, and Issue alerts promptly.

Strategic Outcomes with Incubator Group

Key Design Highlights

Compared with traditional artificial incubation methods, incubators are becoming more and more automated. OUKE incubator can not only automatically turn eggs, automatically adjust temperature and humidity, etc., but also monitor various indicators during the incubation process in real time through an intelligent monitoring system, and Issue alerts promptly.

- Automatic Egg Turning

- Temperature Control

- Humidity Control

- Real-time Monitoring

- Alert System

- Energy Efficient

Key Operating Metrics

Automation

Fully Automated System

Egg Turning

Automatic Egg Turning

Temperature Control

Automatic Temperature Control

Operational Benefits

- Intelligent Automation

- Labor Cost Reduction

- High Efficiency

Application Scenarios

- Hatcheries

- Breeding Farms

- Commercial Incubation

Key Operating Metrics

Benchmarks based on live installations in hot & humid regions, validated against manual cage operations.

Automation

Fully Automated System

Egg Turning

Automatic Egg Turning

Temperature Control

Automatic Temperature Control

Humidity Control

Automatic Humidity Control

Monitoring

Real-time Intelligent Monitoring

Alerts

Prompt Alert System

Efficiency

High Hatching Rate

Energy Saving

Energy Efficient Design

Target Markets

Keywords

Insights Summary

Compared with traditional artificial incubation methods, incubators are becoming more and more automated. OUKE incubator can not only automatically turn eggs, automatically adjust temperature and humidity, etc., but also monitor various indicators during the incubation process in real time through an intelligent monitoring system, and Issue alerts promptly.

This increase in automation effectively reduces labor costs and improves work efficiency, which is of great significance to the operation and management of farms.

Advanced automatic egg turning system ensures proper embryo development and prevents adhesion to shell walls.

Precise temperature regulation maintains optimal conditions throughout the incubation period for maximum hatch rates.

Intelligent humidity control system automatically adjusts moisture levels based on incubation stage requirements.

Smart monitoring system tracks all critical parameters and provides instant feedback on incubation conditions.

Prompt alert notifications ensure immediate response to any deviation from optimal conditions.

Advanced design reduces energy consumption while maintaining superior performance standards.

Automated systems significantly reduce the need for manual intervention, lowering operational costs.

Consistent automated processes deliver higher hatch rates and better chick quality compared to manual methods.

Executive Overview

Technical Advantages

Egg Candling System:

- Custom made according to egg tray requirements (e.g. 63, 150, 176, etc.)

- Equipped with remarkably dependable automatic control system

- Unique patented egg tray detector technology

- Energy efficient high intensity, low voltage LED lights

- User friendly and easy to maintain design

Gallery Highlights

5 photosSystem Flow

Automation modules at a glance

Alert System

Prompt alert notifications ensure immediate response to any deviation from optimal conditions.

Materials & Durability

Improved Efficiency

Improved Efficiency

Consistent automated processes deliver higher hatch rates and better chick quality compared to manual methods.

Operational Metrics

Key performance signals

Automation

Fully Automated System

Egg Turning

Automatic Egg Turning

Temperature Control

Automatic Temperature Control

Humidity Control

Automatic Humidity Control

Model Specifications

Choose the perfect model for your needs

| Model | Type | Capacity | Material | Features | ProductDetail.specifications.applications | Automation |

|---|---|---|---|---|---|---|

| Egg Candling System | — | Custom Made (63, 150, 176 eggs) | — | Automatic Control, Patented Detector | Quality Inspection | — |

| LED Lighting System | High Intensity LED | — | — | Energy Efficient, Long Lasting | Egg Candling | — |

| Control System | — | — | — | User Friendly, Easy Maintenance | System Management | Remarkably Dependable |

| Structural Components | — | — | Anodized Aluminum | Corrosion Resistant, Heat Dissipation | Main Structure | — |

* The above data is standard configuration parameters, specific specifications can be customized according to customer requirements

Related Products

Based on the product you are currently viewing, we recommend other related equipment

TechPro Layer Cage System

TechPro Layer Cage System - 'MORE TECH, MORE EGGS'. Advanced frame-type structure with high automation, featuring automatic feeding, drinking, manure removal, egg collection, ventilation, and IoT-enabled environment control for maximum efficiency and egg production.

Plastic Products

OUKE company produces various plastic accessories to serve chicken farms in every country, including plastic feeder & drinker, automatic plasson, transport crate, plastic floor, etc.

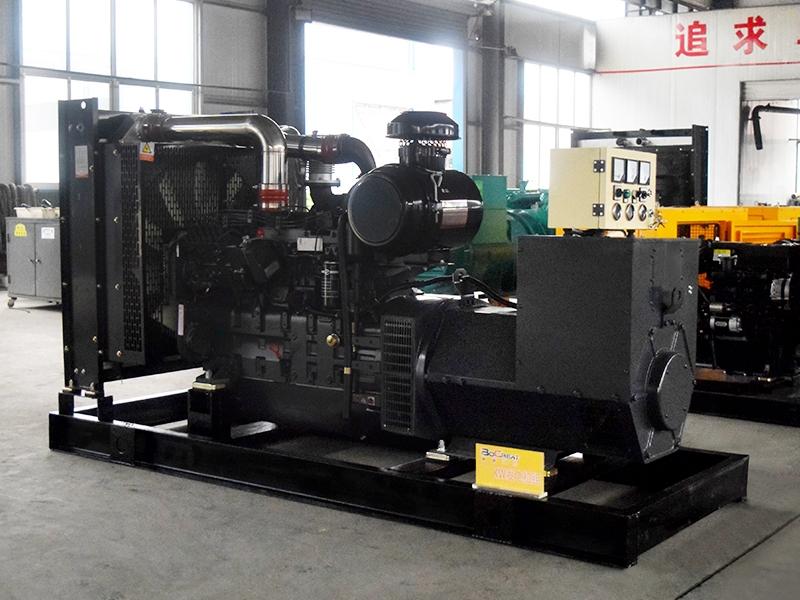

Generator Group

OUKE provides different brands generators for poultry farms to choose, such as Cummins, Perkins, Volvo, Weichai, Yuchai, etc.

Have Questions?

Our professional team is ready to provide detailed product consultation and customized solutions