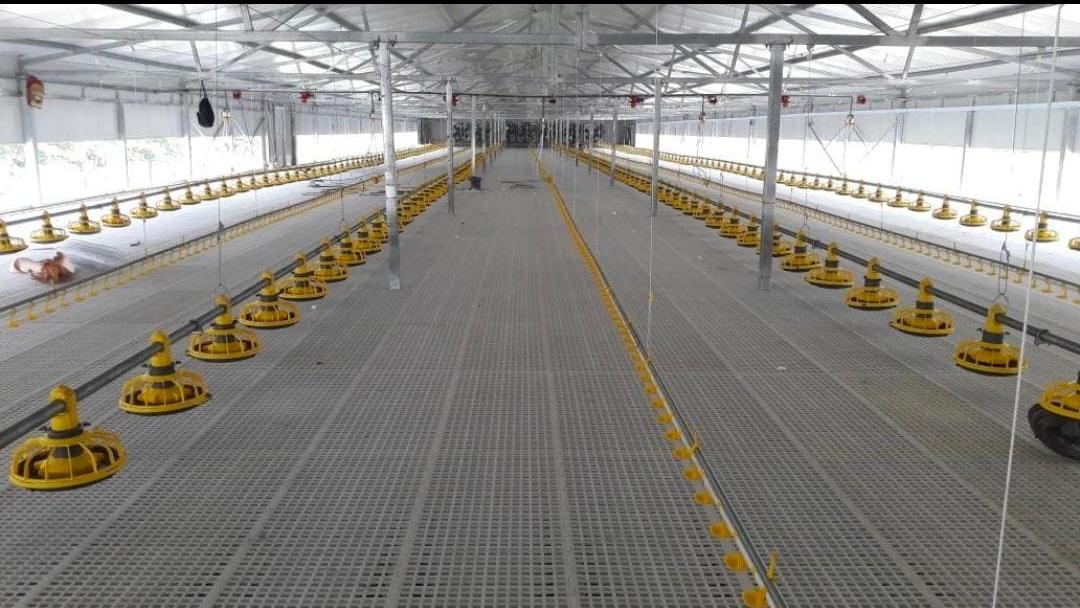

TechFloor Broiler Floor Raising System

TechFloor Broiler Floor Raising System with automated feeding, drinking, and ventilation. Delivers 3 tons feed per hour with intelligent climate control for maximum efficiency.

Strategic Outcomes with TechFloor Broiler Floor Raising System

Key Design Highlights

The TechFloor System represents the pinnacle of modern floor raising technology for broilers and breeders. This comprehensive system integrates advanced feeding, drinking, and ventilation solutions to create the optimal environment for poultry production, maximizing efficiency and output.

- Φ90 Outer Pipe Feed Line with Φ75 Auger

- Dol Brand Feed Dropping Sensor

- 600mm×600mm Vice Feed Hopper

- Hot Galvanized Pan Feed Line

- 360° Water Output Drinking System

- Automatic Nipple Drinkers

Key Operating Metrics

Feed Delivery

3 Tons Per Hour

Automation

Fully Automated System

Water Output

360° Scientific Design

Operational Benefits

- 3 Tons/Hour Feed Delivery

- Automatic Feed Stop Sensor

- Simplified Pressure Regulator

Application Scenarios

- Broiler Floor Raising

- Breeder Floor Raising

- Commercial Poultry Operations

Key Operating Metrics

Benchmarks based on live installations in hot & humid regions, validated against manual cage operations.

Feed Delivery

3 Tons Per Hour

Automation

Fully Automated System

Water Output

360° Scientific Design

Material Quality

Hot Galvanized and ABS Materials

Climate Control

Intelligent Automatic Control

Efficiency

High Operational Efficiency

Target Markets

Keywords

Insights Summary

The TechFloor System represents the pinnacle of modern floor raising technology for broilers and breeders. This comprehensive system integrates advanced feeding, drinking, and ventilation solutions to create the optimal environment for poultry production, maximizing efficiency and output.

Designed with cutting-edge automation and intelligent controls, the TechFloor System delivers 3 tons of feed per hour through its Technical System augers, while maintaining perfect environmental conditions through its customized controller. The system is equally suitable for both broiler and breeder operations, offering unmatched versatility and performance.

The TechFloor feeding system is engineered for high-capacity, efficient feed delivery:

Φ90 outer pipe with Φ75 feed auger from Technical System

Delivers 3 tons of feed per hour

Equipped with Dol brand feed dropping sensor

Automatic feed stop functionality

600mm × 600mm intermediary hopper

Transfers feed from silo to pan feeders

Ensures continuous feed supply

Gallery Highlights

5 photosSystem Flow

Automation modules at a glance

VENTILATION SYSTEM

Comprehensive climate control for optimal bird health and performance:

- Speed-controlled operation

- Provides comfortable temperature

- Removes harmful gases

- Maintains ideal air quality

Feeding System Specifications

- Main Pipe: Φ90 outer diameter

- Auger Size: Φ75 feed auger

- Feed Capacity: 3 tons per hour

- Sensor: Dol brand automatic stop sensor

Drinking System Specifications

- Regulator: Simplified pressure design

- Spout: 360° water output

- Drinker Type: Automatic nipples

- Flow Options: Low or high flow selectable

Ventilation System Specifications

- Fans: Variable speed control

- Curtain: Fast-rolling mechanism

- Cooling: Pad with circulation system

- Heater: Multi-fuel compatible

Materials & Durability

Durable Materials

Durable Materials

Hot galvanized steel and ABS materials provide long-lasting performance in harsh poultry farming environments.

Operational Metrics

Key performance signals

Feed Delivery

3 Tons Per Hour

Automation

Fully Automated System

Water Output

360° Scientific Design

Material Quality

Hot Galvanized and ABS Materials

Related Products

Based on the product you are currently viewing, we recommend other related equipment

TechPro Layer Cage System

TechPro Layer Cage System - 'MORE TECH, MORE EGGS'. Advanced frame-type structure with high automation, featuring automatic feeding, drinking, manure removal, egg collection, ventilation, and IoT-enabled environment control for maximum efficiency and egg production.

Plastic Products

OUKE company produces various plastic accessories to serve chicken farms in every country, including plastic feeder & drinker, automatic plasson, transport crate, plastic floor, etc.

Incubator Group

OUKE incubator can not only automatically turn eggs, automatically adjust temperature and humidity, etc., but also monitor various indicators during the incubation process in real time through an intelligent monitoring system, and Issue alerts promptly.

Have Questions?

Our professional team is ready to provide detailed product consultation and customized solutions