Prefab Building

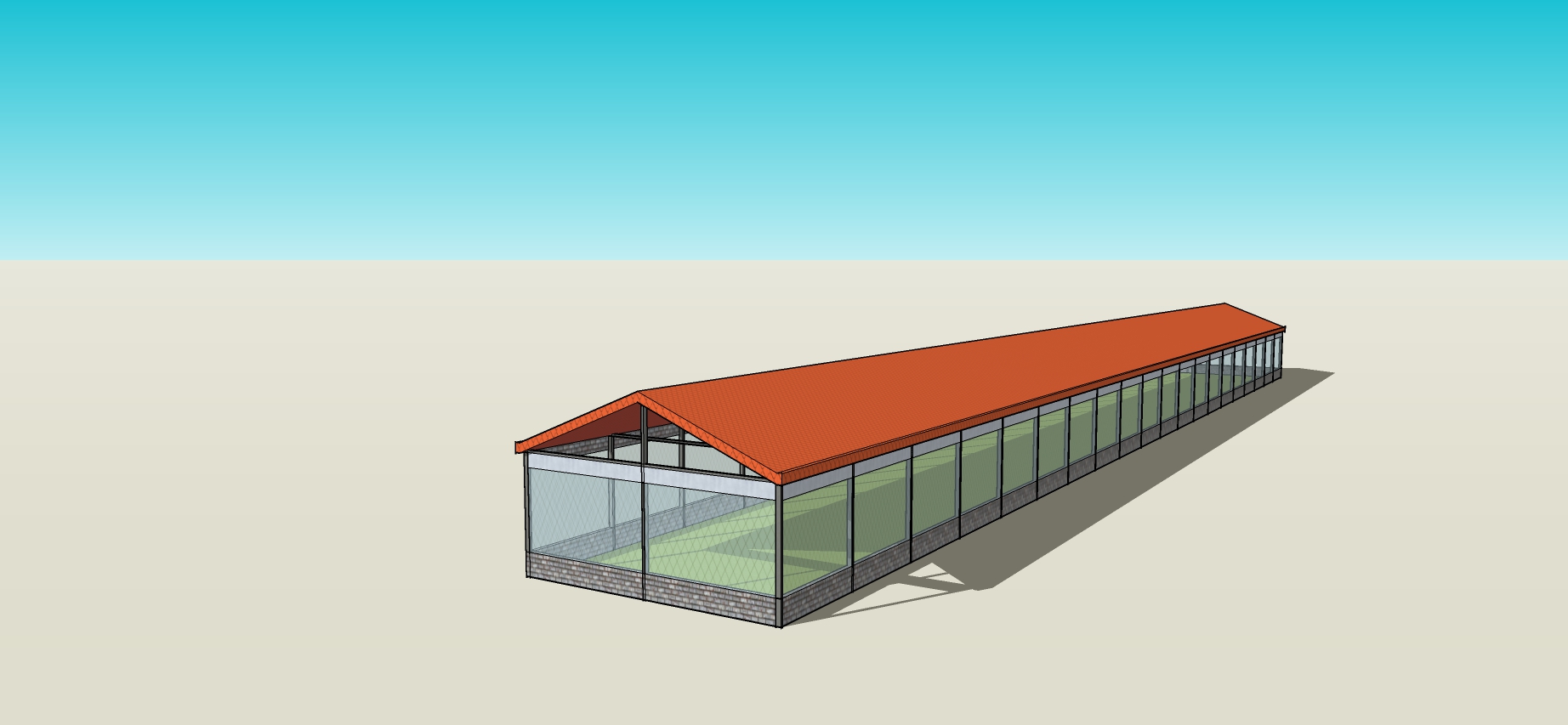

OUKE prefab structure house is used widely in the modern poultry farm. It consists of steel frame system, roofing and ceiling system, wall and cables system and other components.

Strategic Outcomes with Prefab Building

Key Design Highlights

OUKE prefab structure house is used widely in the modern poultry farm. It consists of steel frame system, roofing and ceiling system, wall and cables system and other components. The quick assembly, quick extension, quick shaping and sealability of modern steel structure chicken houses provide a reliable and high-quality environment for intensive chicken raising.

- Quick Assembly

- Thermal Insulation

- Corrosion Resistance

- Lightweight

- High Strength

- Strong Wind Resistance

Key Operating Metrics

Structure

Steel Frame Construction

Insulation

Good Thermal Insulation

Durability

Long Service Life (up to 50 years)

Operational Benefits

- Long Service Life

- Recyclable Materials

- Comfortable Environment

Application Scenarios

- Poultry Farms

- Livestock Housing

- Agricultural Facilities

Key Operating Metrics

Benchmarks based on live installations in hot & humid regions, validated against manual cage operations.

Structure

Steel Frame Construction

Insulation

Good Thermal Insulation

Durability

Long Service Life (up to 50 years)

Corrosion Resistance

Galvanized Steel Material

Installation

Quick and Easy Assembly

Flexibility

High Flexibility for Various Designs

Wind Resistance

Strong Wind Resistance (up to 70 m/s)

Target Markets

Keywords

Insights Summary

OUKE prefab structure house is used widely in the modern poultry farm. It consists of steel frame system, roofing and ceiling system, wall and cables system and other components. The quick assembly, quick extension, quick shaping and sealability of modern steel structure chicken houses provide a reliable and high-quality environment for intensive chicken raising.

With the improvement of chicken cage equipment and the ease of construction of steel structure chicken houses, it has become a reality that a chicken house can raise 100,000 chickens, saving labor and achieving new goals of high-yield and efficient breeding.

Modern steel structures allow for rapid construction, reducing downtime and enabling faster operational readiness.

Good thermal insulation properties provide a comfortable environment for the growth of chickens, enhancing their welfare and productivity.

Galvanized steel materials ensure long-lasting durability and resistance to rust, suitable for various environmental conditions.

The lightweight nature of the materials allows for easy handling and installation, making construction efficient and less labor-intensive.

Designed to withstand extreme weather conditions, these structures can endure winds up to 70 meters per second.

Steel structures can last up to 50 years, significantly outlasting traditional concrete buildings.

Approximately 80% of the materials used in steel structures can be recycled and reused, promoting sustainability.

The high flexibility of steel structures allows for customization to meet various project requirements.

Gallery Highlights

5 photosMaterials & Durability

Corrosion Resistance

Corrosion Resistance

Galvanized steel materials ensure long-lasting durability and resistance to rust, suitable for various environmental conditions.

Operational Metrics

Key performance signals

Structure

Steel Frame Construction

Insulation

Good Thermal Insulation

Durability

Long Service Life (up to 50 years)

Corrosion Resistance

Galvanized Steel Material

Model Specifications

Choose the perfect model for your needs

| Model | Features | ProductDetail.specifications.applications | ProductDetail.specifications.benefits | ProductDetail.specifications.properties |

|---|---|---|---|---|

| Steel Structure | Quick assembly, quick extension, sealability | Intensive chicken raising | — | — |

| Thermal Insulation | — | Comfortable environment for chickens | — | Good sealing properties |

| Galvanized Steel | Anti-corrosion and anti-rust capabilities | Durability in various project regions | — | — |

| Lightweight Design | — | Construction unaffected by seasons | High strength and quick installation | — |

* The above data is standard configuration parameters, specific specifications can be customized according to customer requirements

Related Products

Based on the product you are currently viewing, we recommend other related equipment

TechPro Layer Cage System

TechPro Layer Cage System - 'MORE TECH, MORE EGGS'. Advanced frame-type structure with high automation, featuring automatic feeding, drinking, manure removal, egg collection, ventilation, and IoT-enabled environment control for maximum efficiency and egg production.

Plastic Products

OUKE company produces various plastic accessories to serve chicken farms in every country, including plastic feeder & drinker, automatic plasson, transport crate, plastic floor, etc.

Incubator Group

OUKE incubator can not only automatically turn eggs, automatically adjust temperature and humidity, etc., but also monitor various indicators during the incubation process in real time through an intelligent monitoring system, and Issue alerts promptly.

Have Questions?

Our professional team is ready to provide detailed product consultation and customized solutions